Features & Specs

- Introduction

- Structure

- Operation

- Options

- Specifications

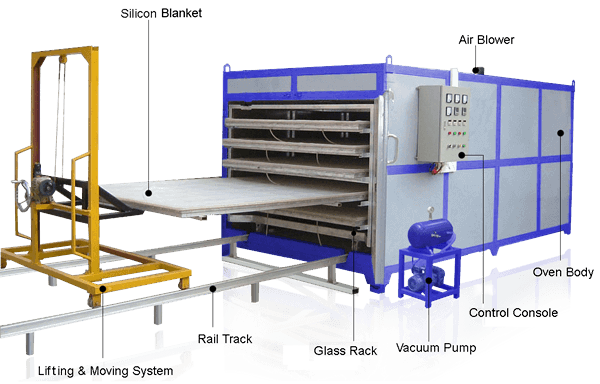

Structure

Oven Body

It consists of surface well-treated thick steel sheets. Double jackets are design on both sides of oven body. Heating elements put inside the double jackets. The steel sheets are constructed in double layers fully filled up with special heat insulation materials. This is to reduce heat loss to minimize power consumption. Outward opening doors with handles are well insulated too. The doors are well sealed when they are close.

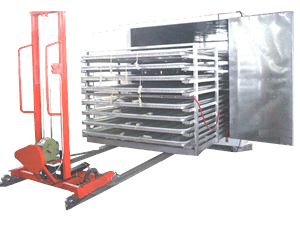

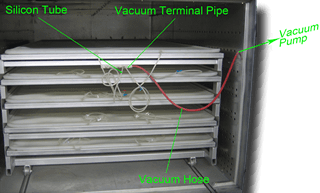

Glass Rack

This 5 storey glass rack is made of sturdy tubular steel structure. Each storey is consisted of a horizontal steel frame which could be slide in and out. A set of silicon blanket are horizontally mounted on each frame. There is a metal vacuum pipe well mounted in front of the glass rack. It is connected to a vacuum pump by a large piece of flexible silicon. Each set of silicon blanket comes with a piece of small silicon tube which is connected or disconnected easily to the metal vacuum pipe with manual control valves to allow vacuum closing or opening of each of the silicon blanket. The glass rack comes with four wheels lying on rail tracks for pulling out or pushing in the oven.

Silicon Blankets

There are totally 5 silicon blankets. Each silicon blanket is put on every storey of glass rack. Silicon blanket is the core of glass vacuum & heating laminating oven. This carefully selected vacuum rubber blanket is made of durable high temperature resistant silicon. It is strong, durable but flexible allowing easy handling. Each set of this integrity silicon blanket consist of one top and one bottom sheets. The fours edges of top and bottom sheets are embedded to each other firmly. The corrugated tooth is specially designed in such a way that the higher the vacuum, the tighter is the seal. This sophisticated tight seal feature prevents from air leaking during vacuuming on one hand while allows easy opening on the other. The top blanket is more soft and flexible than bottom sheet. It allows top blanket elastic enough to wrap around and get in physically direct contact with glass surface and edges thoroughly to guarantee no air is trap inside, which may do harm to perfect vacuuming. Each silicon blanket comes with silicon tube which is eventually connected to vacuum terminal pipe leading to vacuum pump. This silicon blanket is universal applied in all types of Xinology vacuum & heating glass laminating machine.

Vacuum System

A reliable and durable vacuum pump is located outside the oven. A long piece of vacuum silicon hose is connected from the vacuum pump to the metal vacuum terminal pipe inside the oven via a well sealed hole on oven body. Silicon tube of each silicon blanket is plug into vacuum terminal pipe. Vacuum pump generates enough power of vacuum and thus, sucks air out in between top and bottom silicon sheets. The powerful vacuum pump guarantees de-airing of laminated glass thoroughly and prevents bubbles from forming. It is design to run 24 hours a day and 7 days a week.

Heating System

The heating system is consisted of carefully selected heating resistant elements putting inside the double jackets of the oven body. During hot air convection, air passes through double jacket of oven and is re-heated when it gets in contact with heating elements.

Hot Air Blower System

Powerful fan blowers are used to create hot air circulation system inside oven. When it is turned on, hot air is sucked and passes through in between every two storey of glass rack. The hot air heats up the silicon blanket and thus, laminated glass. The air then runs into double jackets on both oven sides and is then re-heated by heating elements. The heated air is sucked again passing through each storey of glass rack again. This uninterrupted heat circulation system provides fast and strong forced convection heating on laminated glass. There is a switch plate putting in an opening where hot air passes through. This plate could be turned in and out to control opening size. When opening size is large, more hot air quantity passes through and, vice versa.

Cooling Air Blower

After oven is kept for certain while at maximum setting temperature, this air blower is turned on to cool down the laminated glass until it is cooled enough for unloading.

Electrical Control

Control console is located at oven side. It is used to control rising, constant and lowering of temperatures and corresponding timing. When a parameter is set for a certain batch of glass lamination, this parameter is stored in memory. It could be taken out immediately when the parameter is found useful for other batches. Vacuum pump is also activated from this control console.

Rail Tracks

There are rail tracks on oven floor. They run all the way outside the oven. Rail tracks outside oven lies above floor. No floor foundation is required. Glass rack moves in and out of oven freely along the rail tracks. A lifting and moving system also gets close to or away from oven along these rail tracks outside the oven.

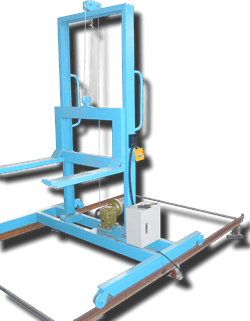

Lifting & Moving System

This system is located outside the oven. It is a strong upright metal tubular construction with an up and down movable metal arm extended horizontally. At tail end of the arm, there is a hook-like structure which is used to lock the silicon blanket frame and pull it out or push it in. A turn wheel, rotated by means of a handle via a gear reduction box, is incorporated behind the metal platform. The handle wheel is used to move the metal platform up and down to level to each of silicon blanket frame. The complete structure lies on rail track which allows it get close or away from the oven.

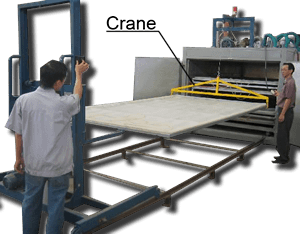

Crane

It is an overhead crane located on oven top right above door. It consists of motor, pulley, metal structure and a crane. The system usually works together with lifting and moving trolley. It is used to hook, support and regulate level of silicon blanket tray when each tray is pulled out by lifting and moving trolley. When upper silicon blanket is pulled out, crane hooks up silicon blanket tray. Crane descends the tray until its level allows operator to load or unload glass comfortably. Similarly, crane raises lower silicon blanket tray until its level allows operator to work comfortably.