Features & Specs

- Introduction

- Structure

- Operation

- Options

- Specifications

Options

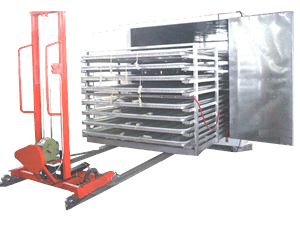

Extra Glass Rack

Standard oven comes with one glass rack. With an optional extra glass rack, production capacity is double. While standard rack is processed inside oven, assembled glass is prepared and loaded in this extra glass rack. When standard rack is done and pulled out from oven, extra loaded rack is put inside the oven for immediate heating. Glass is unloaded and loaded in standard glass rack. This extra glass rack doubles the capacity without any extra oven. The oven is fully utilized with the least idle time.

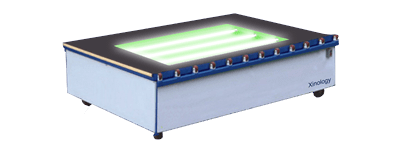

Inspection Table

This is a table with a trough at centre. Several fluorescent lamps are put inside the trough. This is used to inspect and make sure glass is clean enough before assembly.

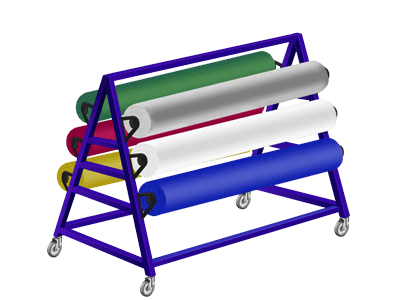

Interlayer Rolls Rack

This tubular metal structure has several horizontal bars with two ends mounted on it. Popular interlay rolls are stored in this rack. This is convenient for rolls handling, unrolling, cutting and piling on glass. Each of bar is easily removed from the structure to allow inserting of interlayer rolls.

Interlayer Cutting & Assembly Table

This table is generally put right next to interlayer rolls rack. Plastic film is unroll and piled on bottom glass. Top glass is also convenient to put on bottom glass with interlayer sandwiched in between. Film cutting is easily done in proper size.

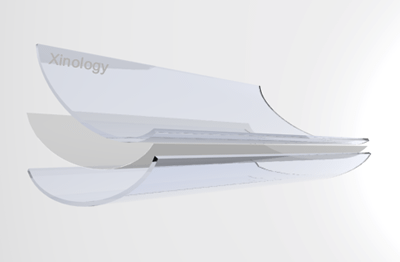

Curve Glass Lamination

After years of research and develop, bend laminated glass could be made from upgraded glass vacuum laminating heating oven without autoclaving.