Overview

Amor Glass

Armor Glass Is Probably The Most And Only Satisfactory Product When Vision And Security Are Required At The Same Time

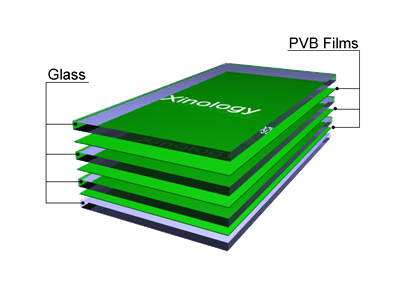

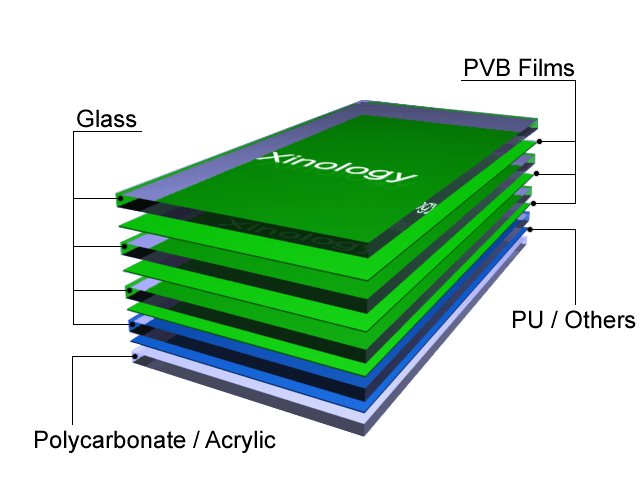

Configuration

Ordinary PVB laminated glass with only two pieces of glass may not provide adequate protection in certain cases. Thicker laminated glass is required for certain applications.

When adequate configuration of multi-layers of glass and proper selected plastic film are laminated together to accomplish certain applications, it is known as armour glass. Armor glass can provide protection in medium to high security applications.

Appearance

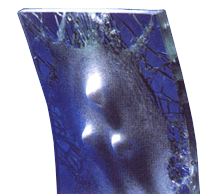

At first glance, armour glass looks identical to an ordinary pane of glass especially when it is framed and no glass section is unable to be seen. Since the glass is very thick, light transmission is low. Sometimes, it may look green because general glass contains iron and thick glass has much higher iron content. Thus, less iron content of ultra clear glass is, when necessary, selected to increase higher light transmission and eventually turns its transparency as close as single pane of glass.

Types

There are many different types of armour glass. They are bullet resistant glass, theft proof glass (or burglary proof glass), hurricane proof glass and explosive proof glass (bomb blasts proof glass), etc.

Applications

The applications of armor glass could be told from its name. Bullet resistant glass is used to stop bullet. Anti-theft glass is used to prevent theft or burglary from penetrating. Hurricane proof glass is used to reduce injuries and property loss as much as it can during storms. Explosive proof glass is used to minimize injuries during explosion especially where there is terrorism. It also helps when there is earthquake.

In prisons, security armour glass can replace traditional bars to create a more humane environment. Armor glass is also extensively applied in military, aeronautical and aerospace industries.

Other than security purposes, armor glass is also applied in staircases and glass floors with proper anti-slipping surface treatment.

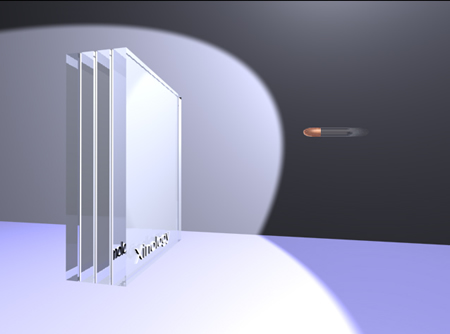

Stop Bullet

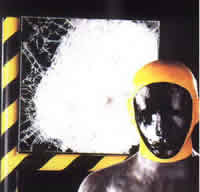

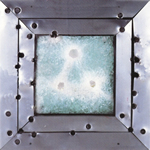

Ballistic glass protection is becoming more and more important due to increasing of urban crime and terrorism. Bullet resistant glass is designed to withstand one or several rounds of bullets depending on the thickness of the glass and the weapon being fired at it.

How does bulletproof glass stop bullets? It is explained by the terms of conservation of energy. When bullet hits on armour glass surface, its energy is appeared in the form of momentum - the mass of bullet and the velocity it travels. A bullet fired at a sheet of bullet-resistant glass will pierce the outside layer of the glass, but the bullet's energy is eventually absorbed by inner glass layers. The glass will stop it before it exits the final layer.

There is also one-way bullet-resistant glass available, which has one side able to stop bullets, while the other side allows bullets to pass through it unaffected. This gives a person being shot at the ability to shoot back. This type of bullet-resistant glass is made by laminating a brittle sheet of material with a flexible material. Imagine a car equipped with this one-way bullet-resistant glass. If a person outside the car shoots a bullet into the window, the bullet would strike the brittle side first. This brittle material would shatter around the point of impact and absorb some of the energy over a large area. The flexible material then absorbs the remaining energy of the bullet, stopping the bullet. A bullet fired from inside the same car would easily pass through the glass because the bullet's force is concentrated on a small area, which causes the material to flex. This causes the brittle material to break outwards, allowing the bullet to pierce the flexible material and strike its target.

The heavier the bullet, the higher the energy it generates. The faster the bullet, the higher the energy it generates. Therefore, different configurations of bullet resistant glass are design to stop different bullets of different weapons. Simply speaking, a rifle bullet will collide with the glass with a lot more force than a bullet from a handgun, so a thicker piece of bullet-resistant glass would be needed to stop a rifle bullet as opposed to a handgun bullet. Polycarbonate

Polycarbonate

A sheet of armour glass is generally made out of all glass. However, there is a disadvantage. When it stops bullet, the outer layer of glass would be pierce by the bullet. The inner layer of glass absorbs the energy. However, the final layer would be splinter into chips. This flying glass chips travel in tremendous velocity and thus, stores enormous energy. They will create serious injuries and property damage despite tiny sizes and light in weight. This, sometimes known as secondary injuries, is also happen in other kinds of armor glass such as hurricane proof glass and explosive proof glass, etc.

A sheet of organic glass is chosen to prevent it from splinter. This organic glass is always used as the final layer. Polycarbonate is extensively used among different types of organic glass due to its strong impact strength and high transparency. A qualified polycarbonate could be more than 10 times tougher than tempered glass.

Polycarbonate could be used as first layer or inner layer of a sheet of armour glass for different applications. Polycarbonate is not as scratch proof as glass. When armour glass is applied in those areas where there are chances to get in direct contact with objects, polycarbonate is not recommended to use as first layer. For example, armour glass for vehicle is generally design not to use polycarbonate as outer layer due to dust in streets. When vehicle travels in high speed, still dust also travels in high velocity relatively when it gets hit on windshield. Thus, it scratches the polycarbonate. The windshield will become blur in long run.

When weight is one of the major concern, polycarbonate is also selected to reduce the weight while not sacrificing impact strength.

When polycarbonate is used, special formulated polyurethane is usually selected, instead of PVB, to be the plastic film interlay between glass and polycarbonate.

Polycarbonate is often known as Lexan, Tuffak or Cyrolon which are brand names of different manufacturers.

Stronger Interlayer

When extra security is required, special formulated security plastic interlayer is used for better protection. The stiffness and toughness are many times more than traditional interlayer.

Thickness and Weight

Simply speaking, the thicker the glass and plastic film, the more safety it is. However, a capable armour glass manufacturer could design a lighter and thinner sheet of bullet proof glass to stop AK47 bullet while an inexperience manufacturer uses thicker and heavier sheet of bullet resistant glass to stop the same bullet.

Two sheets of armour glass with equal total thickness could be made from different thickness of several piece of monolithic glass. For example, there are two sheet of armour glass with two different configurations but with same total thickness, say 50mm. One of the armour glass is made out of three pieces of 15mm glass with approximately 5mm total plastic film thickness. Another is made out of three pieces of 12mm glass, one piece of 10mm glass and 4mm total plastic film thickness. Although they have equal total thickness 50mm, one of the armour glass could fulfill certain application while another could not. Moreover, for the second armour glass, the 10mm glass put in first layer, inner layer or final layer may result in different outcomes.

Generally speaking, all armor glass designers are targeting to reduce the thickness and weight of armour glass and meanwhile, remains its characteristics unchanged or even better. After all, customers would rather prefer less expansive, thinner and lighter armour glass especially armour vehicles owners who concern safety on one hand but also fuel energy on the other.

Calculation, trial and test are required to find out thinner and lighter configurations of armour glass to accomplish same task that thicker and heavier armour glass is required before. This technology know-how is the heart of a well experience armor glass manufacturers.

Some designers has already begun to use thin chemically strengthen glass as one of the composition of armour glass to reduce the thickness and weight drastically. The chemically strengthen glass could be 2mm or even 1mm and less. Chemically strengthen glass is few times tougher than thermally tempered glass. 1mm or thinner chemical strength glass is flexible, while tough, and could be bent with conventional curve glass at room temperature. This feature allows versatile applications of armor glass and is began more popular by armour glass designers.

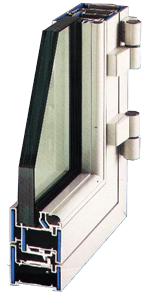

Framework

Like ordinary window and door, most of armour glass is also installed with framework. Framework section should be specially design. Framework material should be carefully selected. It should be as tough as the armor glass.

When glass is made bulletproof, do not forget to make framework also bulletproof.