Features & Specs

Operation

Glass Inspection

Glass is placed on an optional inspection table with fluorescent lamps lies beneath the glass. Operator inspects and makes sure the glass is clean enough for assembly.

Interlayer Cutting & Assembly

Several rolls of popular interlayer film are stored on a roller rack which is located right next to glass inspection table. Required interlayer is unrolled and lay flat on glass. Second piece of glass, after inspection, is put on top of the interlayer. The two pieces of glass is aligned in proper position. It is then cut in requested size. If multiple layers of glass and interlayer are required, the assembly cycle is repeated.

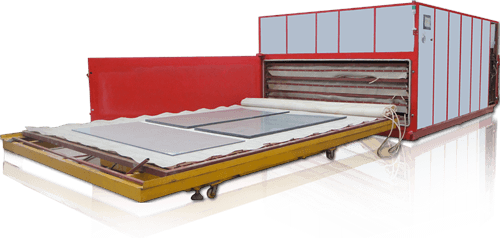

Glass Loading

Oven door is open. Optional scissors lifts or rail rack, depending on drawer supporting design, is brought right next to oven. Drawer is pulled out until it is safely supported by optional scissor lifts or rail rack. Top silicon blanket is unrolled. Lay up glass is loaded on bottom silicon blanket. After glass is well-loaded, top silicon blanket rolls up. Edges of top and bottom silicon blanket are tightly sealed. Small Silicon hose is well connected to vacuum terminal. The drawer is pushed back to oven. If there are more glass, next drawer is pulled out and loading cycle is repeated until all glass is loaded or oven is fully loaded with glass. Optional scissor lifts or rail rack is removed away. Oven door is closed and locked.

Vacuum & Heating

Working parameters and profiles are set in PLC via touch panel operator interface. Heating and vacuum process are started automatically. Air is started to remove in between top and bottom silicon sheets. If there are some drawers with empty glass loading, heating elements for these drawers are not switched on. Only heating elements of those drawers with glass loaded are switched on. This design saves heating power.

Cooling

When heating is completed, heating elements are shut down. Door is opened. Drawer is pulled out and supported by optional scissor lifts or rail rack. If necessary, extra fan (to be provided by buyer) is required for fast cooling. Vacuum remains power on all the time.

Glass Unloading

When laminated glass is cool enough, vacuum is turned off. Silicon blanket edges are unsealed. Top silicon blanket is unrolled. Well done laminated glass is ready for unloading.