GLASS LAMINATING

Flat Glass Roller Press PVB Laminating Line

- Two Pairs of Press Rolls Glass Laminated Line

- Two Heating Ovens for Glass Laminating

- Glass Well Sealed after Heating & Pressing

- Vacuum Suction Lifting System for Easy Glass Assembly

- Perfect Glass Registration for Excellent Top & Bottom Glass Alignment

- Multi-Layer Glass Assembly & Laminating

- Roller Conveyor for Continuous Glass Handling

- Washing Machine Cleans Glass Prior to Assembly

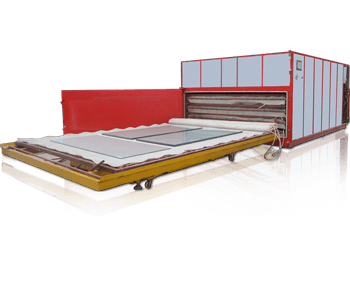

Autoclave-Free PVB Laminated Glass Production Oven

- Truly Autoclave-Free Oven Producing PVB Laminated Glass

- Requires No Vacuum Bags, No Rubber Rings And No Rollers Presses.

- PVB Laminated Glass Absolutely Free Of Bubbles & No De-Lamination.

- Produces also EVA Laminated Glass

- No Air Conditioner & No De-Humidifier Are Required.

- No Climatic Control Room Is Required For The Oven.

- PVB Assembly Can Be Done At Room Temperature Without Climatic Control Room.

- PVB Is No Need Stored In Climatic Control Room.

Autoclave-Free EVA Laminated Glass Production Oven

- Autoclave Free Laminated Glass Manufacturing

- Require No Roller Press Nor Climatic Control Room

- One Step Process Making Two Panes or Multi-Layer

Laminated Glass - Free of Vacuum Bags

- Durable Heat Resistant Air Tight Silicon Blankets Guarantee Perfect Vacuum

- Suitable for EVA any other Proper Interlayer Films

- Produces Flat & Curve Laminated Glass

- Two Kinds of Ovens Available with 5 & 2 Silicon Blankets

Glass Laminating Autoclave

- Pressure Vessel for Laminated Glass Final Bonding

- Multiple Devices for Safety Purposes

- High Performance Heating System

- Carefully Selected Materials & First Class Welding Workmanship

- Air Storage Tank for Air Filling into Autoclave

- Handling System for Easy Glass Movement

- Optional Vacuum System for Bonding of Curve or Armour Glass

Glass Laminating Vacuum Bagging Films

- Alternative Process for Glass Laminating

- Substitution of Roller Press & De-airing Oven

- Film Turns into Vacuum Bag in Minutes

- Design for Flat & Curve Laminated Glass or Armour Glass Production

- Durable Anti-Tear Specially Formulated Plastic Films

- High Temperature Resistant Suitable For Autoclaving

PDLC Smart Glass & Film

- Also Known As Intelligent, Privacy, Liquid Crystal, LC,

Switchable or Electrochromic Glass - Switchable Instantaneously between Transparent & Opaque

- Applicable wherever Privacy is Concerned

- Suitable for Commercial, Residential, Recreation & Industrial Purposes

- Available in Clear & Transparent Colour Smart Glass

- Easy Process Turns Film into Glass

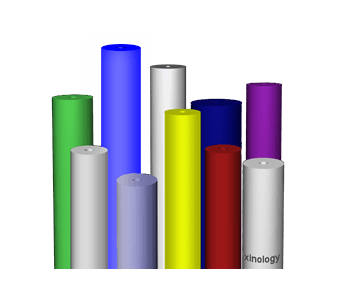

EVA Interlayer Film

- Most Adequate Film Substitutes PVB

- Excellent Transparency at Lowest Haze

- Outstanding Adhesion with Glass

- Inert to Moisture & Vapour

- No Climatic Control Room Required for Glass Assembly

- Handling & Assembly at Room Temperature & Humidity

- Available in Transparent, White, Variety Clear & Opaque Colors

- Available in 0.25mm, 0.38mm & 0.76mm Thickness

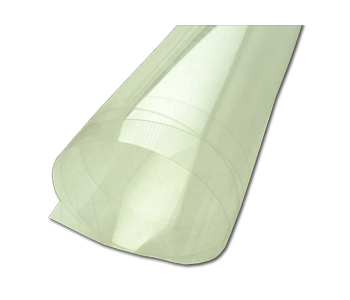

Back Film for Single Pane Glass Laminating

- Design to Produce Laminated Glass with Single Glass

- Suitable to Make Light & Thin Shatter Proof Glass

- Glass with or without Decorative Graphic Interlayer

- Applied for Movable Glass Doors or Any Other Areas where Light & Thin are Major Concern

Vacuum Silicon Blanket for Laminated Glass

- High Temperature Resistant

- Patent Edge Seal Design Guarantees Perfect Air Tight During Vacuum

- Strong but Soft

- Anti-Deterioration

- Flexible High Tensile Strength Materials for Easy Handling

- Durable Silicon Lasts for Years

- Holds Several Pieces of Glass at One Time

- Available in Variety Sizes

Vacuum Silicon Rubber Ring

- Wrap Around Laminated Glass Edges

- High Temperature Resistant

- Strong but Soft

- Anti-Deterioration

- Flexible High Tensile Strength Materials for Easy Handling

- Durable Silicon Lasts for Years

- Available in Variety Length or Perimeter for Different Sizes of Laminated Glass

Liquid Resin for Laminated Glass

- Ready-To-Use Single Component Liquid Resin

- Available in UV Cured & Heat Cured Liquid Resins

- Require No Machine, No Dosing, No Scaling & No Mixing

- Simple & Easy Operation

- Excellent Impact Strength Resistance

- Ultra High Light Transparency & Low Haze

- No Delamination

- Meets International Safety Glass Standards

PVB Interlayer

- Extraordinary Bonding Strength with Glass

- Outstanding Tensile Strength

- Free of Particles & Contamination

- Anti-UV & Anti-Aging

- Anti-Splinter Safety Glass Tightly Sticks Shatter Glass on Film

- High Penetration Resistant Security Glass Prevents from Penetration

- Sound Proof Laminated Glass for Comfort Window & Door

- Armor, Explosion & Hurricane Proof Glass with Multi-Glass & PVB Film Layers

The Most Comprehensive Selected Top Class Chinese Glass Machines, Products and Services Resource

The Most Comprehensive Selected Top Class Chinese Glass Machines, Products and Services Resource

Glass Fabricating Machines | Glass Processing Machines | Glass Furnaces | Glass Ovens | Glass Manufacturing & Production Equipments | Glass Accessories | Glass Toolings | Glass Supplies | Glass Consumables | Glass & Mirror | Glass Engineering | Glass Contracting | Glass Consulting | Glass Services- Contact Us | Terms of Use Copyright © 1989 - 2020 Xinology Co., Ltd. All Rights Reserved.