Overview

- IG-ED-SA-A

- IG-ED-SA-B

- IG-ED-SA-C-1

- IG-ED-SA-C-2

IG-ED-SA-C

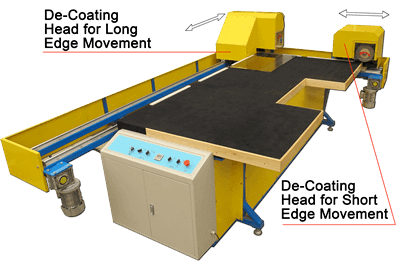

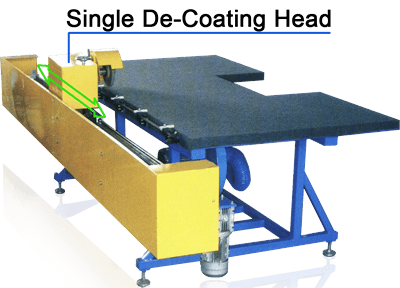

Single or Double Deleting Heads

Available in two types of machine. One is with single glass low-e coating edge deletion spindle motor while another with double spindle motors. The double head machine is for X and Y axis edge deletion.

Sturdy Motor & Spindle

Grinding motor and spindle are made of the best available parts and components. Motor is mounted on track rails used for motor moving guide.

Precision Track Rails

Grinding motor platform runs on track rails. The sturdy high precision track rail guarantee the grinding motor running in perfect straightness. A driven motor locates on one end of track rails. It is used to drive grinding motor along track rails.

Air Floatation / Suction Table

Table is covered with felt. The felt is so smooth such that it does not scratch glass. There are many holes on the table. An air blower locates under the table. Hoses are connected between air blower and table. Air blower is reversible. It could create air cushion and suction on table. This design eliminates physical contact with low-e coating during handling and edge deletion.

Scrap Suction System

There is a powerful suction system which is installed next to low-e edge de-coating wheel. It evacuates all particles and dust generated during edge deletion.

Operation

1. Air blower is turned on. Air cushion is created on table surface. Low-e glass is loaded on air floatation table with low-e coating upward. When glass is in position, air blower is reversed. Vacuum is created and glass is then sucked and fix on table.

2. The system detects the starting point of low-e edge. The grinding motor begins to run from one end till the other end of glass edge by driven motor. It stops automatically at edge end. Low-e edge is then deleted. For double grinding heads machine, another grinding motor begins to run from one end till the other end of glass by driven motor. It stops automatically at edge end. Another low-e edge is also deleted.

3. By press buttons, air blower stops suction and reverses to create air cushion. Glass is then manually turned 90 degrees. Repeat de-coating process mentioned above until other two edges are deleted. Single grinding head machine requires three turning of glass until all 4 edges are low-e deleted while double heads machine required only one turning.