Features

Operation

Washing

First piece of glass is loaded on glass washing machine. Glass is then washed thoroughly by cylindrical brushes. It is then pre-dried by sponge and final dried by air knife.

Assembly

Rubber spacer strip coil is loaded in turntable beneath floatable table. Air blower of this table is turned on. Air cushion is created on table surface via tiny holes. After washing, glass is moved and float on this table until it is positioned on center hole. Vacuum suction cup goes up and hold the glass in position. Operator takes the rubber spacer strip out from the coil beneath table. It is then applied around glass rim by turning the glass until one round of perimeter is made.

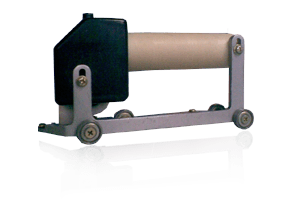

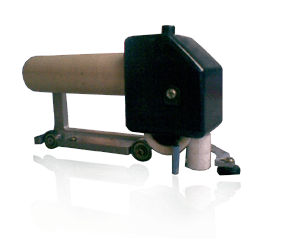

A special but simple design ultra light handheld tool helps to apply rubber strip along glass edges and corners turning in proper position in seconds. This tool is optional.

Tilting

First piece of glass with spacer strip is then moved to this ball castor table. The table is then tilt up. Meanwhile, second piece of glass is washed and pass on to assembly table. It is then removed and paired on first piece of glass while it is inclined on tilting table. When it is well assembled, the table goes down to horizontal. Glass is then conveyed downstream.

Hot Rollers Pressing

Well assembled insulated glass finally enters into this machine. It is firstly heated up to slightly melt the rubber until it is soft enough for sealing. Glass then passes through top and bottom press rollers for final sealing. Insulated glass is then unloaded at exit end.