Features & Specs

Tilting Conveyors with Motorized Vertical Glass Movement

Features

- This Glass Tilted Conveyor is Made of Sturdy Welded Tubular Steel Painted with Top Quality Varnish

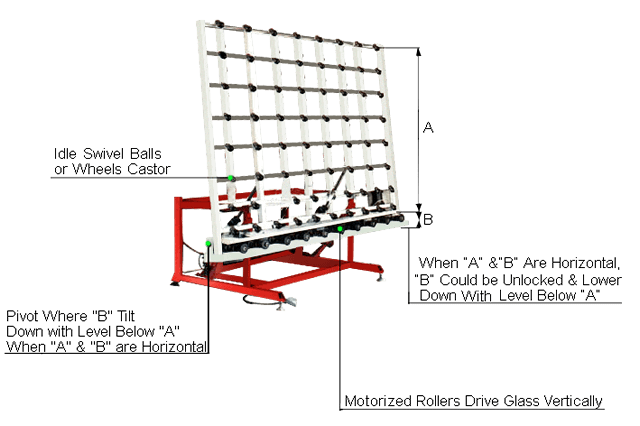

- Idle Scratch Free Castor Balls of Upper Sections for Glass Leaning Support when Glass is Being Driven Vertically & for Glass Horizontal Freely Movement Manually when Upper Section is Titled Down Horizontally

- Rollers of Bottom Section are Electrically Driven by means of Chains

- Glass Tilting Activated by Powerful Cylinders

- Shock Free Tilting Motions Especially When Approaching Horizontal Position

- Glass Travels Vertically

- Glass Convey Speed Adjustable by Speed Regulator

Specifications

| Models | GH-TH-C-1020 | GH-TH-C-1525 | GH-TH-C-2030 | GH-TH-C-2537 | GH-TH-C-3361 |

| Max. Glass Size (mm) | 1000 x 2000 | 1500 x 2500 | 2000 x 3000 | 2500 x 3700 | 3300 x 6100 |

| Working Height(mm) | 900 | 900 | 900 | 900 | 900 |

| Max. Glass Loading (kg) | 100 | 160 | 300 | 400 | 900 |

| Tilting By | Pneumatic | Pneumatic | Hydraulic | Hydraulic | Hydraulic |

| Power (KW) | 2 | 2 | 3 | 3 | 5 |

| Weight (kg) | 240 | 450 | 600 | 880 | 1800 |

| Outer Dimensions (LxWxH) (m) | 1.2 x 2.1 x 0.9 | 1.7 x 2.3 x 0.9 | 2.2 x 3.1 x 0.9 | 2.7 x 3.8 x 0.9 | 3.4 x 6.2 x 0.9 |

Option

Individual Bottom Rollers

Rollers conveyor is design in two individual structures with pivot in between,

- upper conveyor with idle castor balls

- bottom rollers conveyor driven by motor

When upper conveyor is in upright position, glass travels vertically by means of motorized driven bottom rollers while glass is leaning and supported on idle ball casters of upper conveyor. When upper conveyor tilts down to horizontal position, row of bottom rollers is detached from upper conveyor with level lower than upper conveyor. The design allows manually loading and unloading of glass when, for example, glass is light and small.