Overview

Introduction

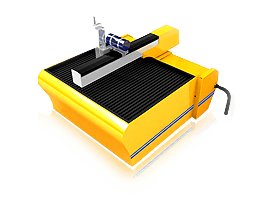

WJ Series of Waterjet System Can Do Things that Other Technologies Simply Cannot

Verastile Water Jet

Water jet is generated when water flows from a high pressure pump, through plumbing and out from a jewel nozzle with tiny opening. At 300 MPa (approxiamtely 40,000 PSI), the water jet exits out of the jewel orifice at Mach 2 (680 m/s or 2,450 Km/hr) while it is over Mac 3 (1,021 m/s or 3,676 Km/hr) when pressure goes up to 400 MPa (approximately 60,000 PSI). This remarkable water jet bears considerable amount of energy which turns into forces for cutting, scoring, trimming, slicing, slitting and cleaning as well.

Water jet cutting systems are the world's most versatile machine tools. Water jet process is also recognized as the most versatile and fastest growing process in almost all industries. The process provides many unique capabilities and advantages. Waterjet has shown that it can do things that other technologies simply cannot.

It is proven to be more beneficial and cost effective than traditional technologies such as, machining, laser, plasma, EDM wire cut, oxy-fuel cut and diamond tool, etc. There are virtually no limits to what water jets are capable of cutting and machining. The machines are extremely easy to use. Operators can handle the machines after few hours training and produce high quality parts in hours. Our water jet system are suitable for production of high volumes, short runs or prototype parts.

The versatility makes abrasivejets drastically popular in the markets in the last few years. Advance technologies, include control, high pressure pumping, high pressure parts and components, has suddenly made everything possible that could not previously be achieved.

Develop of Water Jet

Low pressure water jets were firstly used for gold mining in California, USA in 1852. Steam and hot water jets were used in the early 1900s for cleaning purposes. High pressure water jets were used for mining in the 1960s.

After numerous trials and errors, in early 1970s, it was discovered that water pressure at between 276 MPa and 414 MPa (40,000 PSI to 60,000 PSI) at approximately 0.1mm water jet stream could neatly cut everything from cardboard to disposable diaper. This revolutionary technology was developed for industrial purposes and was applied in those areas that had been failed to cut with knives or mechanical processes. Water jets were then extensively applied in following applications,

- Cardboard

- Disposable diaper

- Insulating material

- Foam rubber

- Gasket material

- Food products

- Fabric

- Leather

- Carpet for automotive applications

These were all soft materials. This was because cutting of hard materials, for example glass, metal, stone and ceramic, was unsatisfactory. Industrialists and scientists continued to investigate.

In early 1980s, in addition to standard water jets components, special nozzle was developed and little amount of abrasive powder was introduced into the water jet and the abrasive such as garnet, ejected out from the nozzle traveling as fast as the water jet. This, so called “abrasive jets”, was able to cut any hard and tough materials such as titanium, stainless steel, glass and ceramics with satisfactory results.