Features & Specs

CUT-AUTO-B

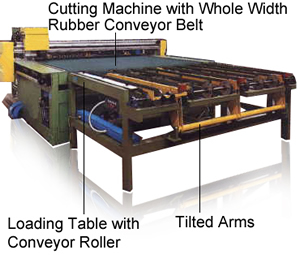

Automatic Glass Cutting Machines with Full Width Conveyor Belt Table

Features

- Automatic Precise Straight & Shape Glass Cutting Machine

- Full Width Conveyor Belt Table Brings Glass in & out of Cutting Machine

- Reinforce Fine Rubber Conveyor Belt provides Perfect Flatness for Thin Glass Cutting

- Heavy Duty Electro welded Tubular Steel Structure with Anti-Rust Painting

- X-, Y-, Z-Axes AC Servo Motors with Drivers

- Precise Abrasive Proof Pinion & Rack

- Heavy gauge steel tubing runs underneath conveyor belt with two rigid side elements carrying guiding rails of the cutting bridge

- Frictionless Cutting Head Cylinder

- Cutting Pressure Controlled by Servo Valve Programmable with Gentle Downward Action Preventing Glass & Cutting Wheel from Damage

- Automatic Glass Cutting Oil Feeding from Pressurized Integrated Lubricant Tank

- Bottom Cylindrical Brush Removes Glass Chips Left on Conveyor Belt During Cutting

- Glass Registration Loading Table prior to Cutting Machine

- Glass Positioned at Side & Leading Edges before Entering to Cutting Machine

- CNC-Processor 64 Bit with Ethernet-Interface

- Integrated PLC

- Digital Input/Output 24VDC

- LCD Touch Screen Panel HMI Human Machine Interface

- User Friendly Operator Interface

- Axis boards for analogue or digital servo control

- Controlled Up to 32 axes & 8 Channels

- Fault Diagnostics Displayed with Clear Text Information

Specifications

| Models | CUT-AUTO-B-0818 | CUT-AUTO-B-1222 |

| Max. Glass Size | 800 x 1830 mm | 1200 x 2250 mm |

| Glass Thickness | 1.6 ~ 6 mm | 1.8 ~ 6 mm |

| Cutting Speed | Max. 90 m/min. | Max. 90 m/min. |

| Cutting Accuracy | ± 0.125 mm | ± 0.125 mm |

| Working Height | 920 ± 25 mm | 920 ± 25 mm |

| Power | 380V / 3 phase / 50Hz | 380V / 3 phase / 50Hz |

| Outer Dimensions (L x W x H) | 2800 x 2200 x 920 mm | 3200 x 2600 x 920 mm |

Options

Glass Loading

Manual Glass Loading with Tilted Arms

Standard registration table installed prior to cutting machine is design for manual glass loading. There are various ways to load glass easier and faster.

Automatic Glass Loading Machine with Tilted Arms, Vacuum Suction Cups & Belt Conveyor

Automatic Overhead Glass Loading with Vacuum Suction Cups

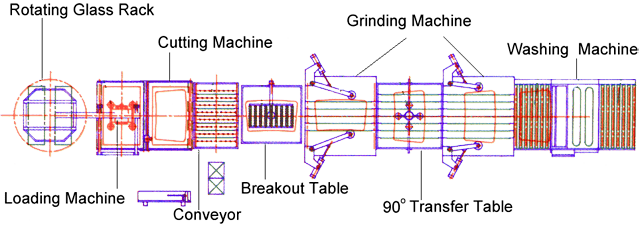

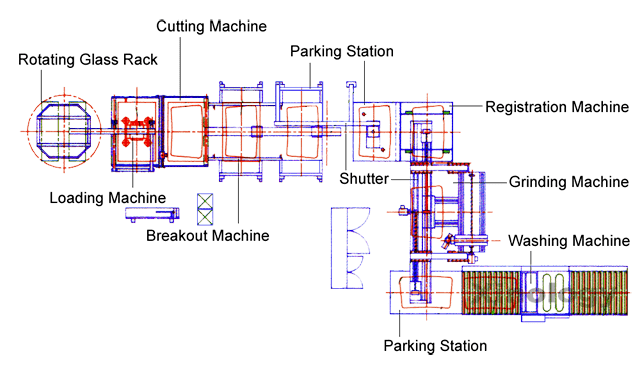

Glass Preprocessing

For high volume production such as automotive glass, downstream machineries could be incorporated with automatic glass cutting machine to form a complete automatic production line. Downstream machines could be breakout, drilling, grinding and washing machines, etc.