Features

BK-M

Introduction

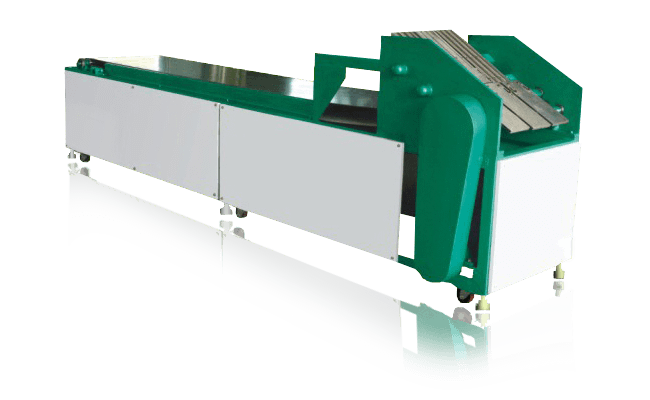

Multiple glass strips loaded in the magazine of BK-M-04 at one time for high productivity. Glass pieces after breakout are brougth out to an extended long belt conveyor for convenient collection.

BK-M-04 is design to breakout long strip glass mechanically into pieces of rectangular and square glass. The major design of this machine is the magazine construction which is able to load several glass strips at one time. BK-M-04 is hundreds times more efficiency than manual breakout. It is a workhorse machine for mass production.

Generally, this series of machine is put right next to XY glass cutting machine. After glass is cross and longitudinal scribe by XY cutter, the glass is, usually manually, breakout into long strip glass. Several glass strips are then loaded into this BK-M machine and they are turned into rectangular and square glass pieces in seconds.

BK-M is very suitable for mass production of glass mosaic, microslide, instrumentation glass, glass for electronic, display glass and glass for lighting, etc.

Highlights

- BK-M is hundreds times more efficiency than manual breakout

- Thousands pieces of rectangular and square glass are breakout in minutes

- Reliable mechanical breakout

- Easy adjustment

- Breakout is done automatically

- One operator can handle the magazine for multiple glass strips feeding

- Lowest possible labor force

- Operation is easy

- Almost free of maintenance

Construction

BK-M-04 is composed of,

- Magazine for loading of several glass strips at one time

- Belt conveyor moves glass automatically

- Driven mechanism to drive belt conveyor.

- Roller used to breakout glass strip into rectangular and square pieces

- Adjustable system to regulate roller pressure

Operation

There are several slots on the magazine. Glass strips are loaded into the slots. The glass strips then slide into the mechanical breakout system where they are breakout into glass chips. The chips are then brought out by the belt conveyor and are collected.

Operator is just required to feed glass strips continuously into the magazine.