Features & Specs

GBO-D Rotary Glass Bending Ovens

Introduction

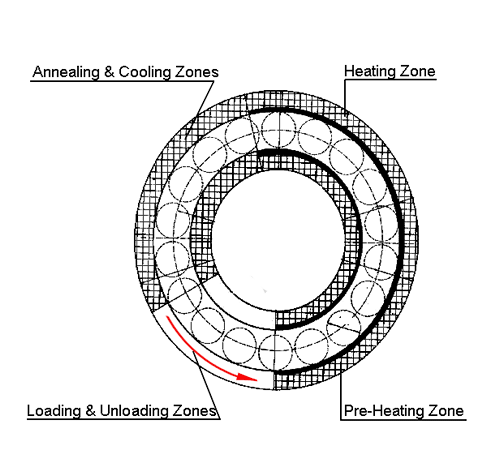

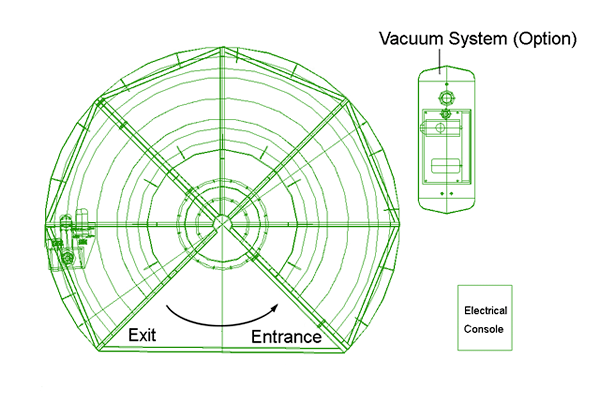

Series GBO-D rotary glass bending ovens is used to bend small medium size of glass. The oven is a rotational design. This oven is specially design to bend car and motorcycle rear view mirrors, cosmetic mirrors, clock glass covers and glass lantern. Glass is bent by means of gravity. Bending of glass or mirrors with small radius of curvature or large bending depth are assisted by optional vacuum system. Glass enters into this circular glass bending oven and exits at the same area after turning one round inside the oven. The rotating automotive mirror bending ovens brings glass via pre-heating, bending, annealing and cooling sections.

Structure

Oven Body

It is a circular steel frame structure painted with high temperature resistant varnish. It is composed of pre-heating zone, heating and bending zones, annealing and cooling zones, loading and unloading areas. Oven walls are insulated with thermal preservation materials.

Heating System

There are heating resistors distributed at top of oven in pre-heating, bending and annealing sections. There are thermocouples measuring real time temperatures.

Rotating System

A circular steel structure, painted with high temperature resistant varnish, freely self rotates inside oven body.

Driving Mechanism

Rotating conveying system is driven by powerful electrical motor with gear reduction box. Rotating speed is adjusted by frequency convertor.

Refractory

The refractory is brick like materials putting on rotating conveying platform.

Control System

It is a standalone electrical control console consisting of PLC, PID temperature controller. They control heating profile and rotating speed.

Options

Vacuum System

When radius of curvature is smaller than 600 mm, glass usually does not bend correctly merely by means of gravity. Optional vacuum system is ancillary to help glass get in proper contact and conform to the shape of bending mould. The refractory brick has many tiny holes. There is a center hole on each of mould which is put on top of bricks. Vacuum hoses with vacuum valves are connected from the vacuum system to bottom of bricks. When glass is heated up to softening temperature, vacuum system is started. Glass is bent by means of vacuum suction. Vacuum pressure is approximately -0.07 ~ -0.04 MPa.

Bending Moulds

Standard ovens do not include bending molds. These top quality bending moulds are made of special high temperature resistance materials. They are non-scratch and leave no mould marks on glass during bending. Sizes of mould are determined by glass sizes which are to be provided by buyer. Numbers of mould are determined by mould sizes. The larger is glass size, less number of mold are required. Buyer is also required to provide radius of curvature of each type of glass.

Specifications

| Models | GBO-D-3600 | GBO-D-5000 |

| Oven Exterior Diameter | Φ 3600 mm | Φ 5000 mm |

| Oven Interior Diameter | Φ 2700 mm | Φ 4100 mm |

| Max. Temperature | 780 ℃ | 780 ℃ |

| Rotating Speed | 10 ~ 15 rotations / hr | 10 ~ 15 rotations / hr |

| Productivity | 150 ~ 200 pcs / hr | 200 ~ 350 pcs / hr |

| Install Power | 100 KW | 120 KW |

| Outer Dimensions (LxWxH) | 3600 x 3600 x 1200 | 5000 x 5000 x 1200 |