Assembly

Options

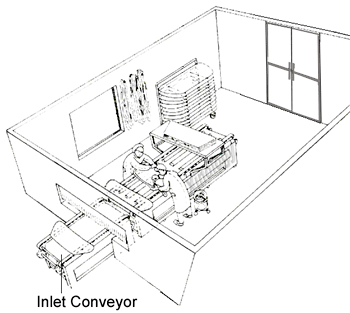

Inlet Conveyor

This optional inlet conveyor transport glass into assembly room through an opening slot. Without this conveyor and slot, glass after bending is usually loaded on glass trolley which is brought inside assembly room through door. This procedure requires more labor force. Inlet conveyor reduces intensive labor and glass handling. The conveyor is usually motorized driven controlled by operations inside assembly room. When operator finds necessary, he pushes a button and inlet conveyor brings glass inside assembly room.

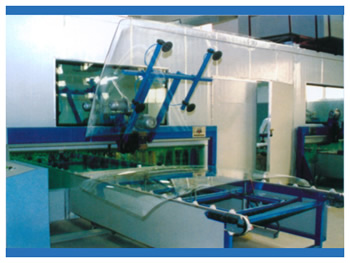

Suction Cups Separator

This option is available when optional inlet conveyor is chosen. A clam shell suction cups device is installed above inlet conveyor outside assembly room. When bent double glass is loaded on inlet conveyor, suction cups tilts down until it gets in contact with glass. Vacuum is activated and suction cups are tilted up until top glass is separated from bottom glass. Bottom glass is conveyed into assemble room. Suction cups descend top glass on conveyor which brings it into assemble room.

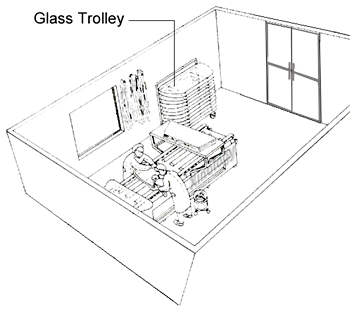

Glass Trolley

Glass trolley is a wheel rack structure where glass is loaded and standby. Loaded glass is usually already assembled with rubber ring. Glass trolley is moved inside cabin oven for pre-heating and vacuum. After de-airing process is accomplished, glass trolley is brought out of cabin oven and glass is ready for unload. Empty glass trolley is then brought back to assembly room for next loading.

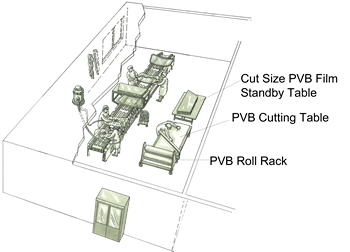

PVB Cutting Table

PVB cutting table include also a PVB standby table and a PVB roll rack. Proper PVB is unrolled from PVB roll rack. Operator cuts PVB in adequate length. Cut size of is stacked on a separate PVB standby table. When it is ready, stack PVB is transferred to PVB bridge rack in line with PVB Assembly Line.