Overview

Glass Configuration

Fire resistant glass is classified into monolithic and lamination or insulation in terms of its configuration.

Monolithic Fire Reststant Glass

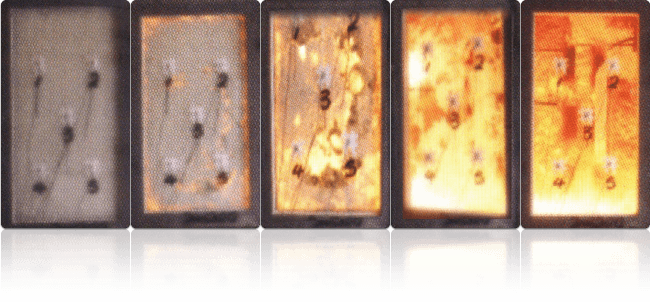

Testing of Monolithic Fire Resistant Glass

General

Monolithic glass is single pane. This fire protective glass blocks flames, fumes and smoke but not heat radiation. Its advantages are:

- As it is not wired or laminated, it stays clear at all times during fire accident so that evacuation and putting out fire could be carried out properly. Clear fire resistant glass offer transparent alternative to solid brick walls.

- It is thermal shock proof and resists to cold, heat, solar irradiation and humidity.

- This high strengthened fire resistant glass is 3 to 5 times stronger than thermal temper glass.

- Various glass thickness of monolithic fire resistant glass is available.

- Monolithic fire resistant glass is light. Framework is cheaper. Mounting and installation is easier at lower cost.

- It is easily upgraded to several types of fire resistant glass such as reflective coated fire resistance glass, insulated fire resistant glass, laminated fire resistant glass and energy save fire resistant glass, etc.

There are several types of monolithic fire rated glazing reaching different classes and grades of fire resistance.

Chemically Strengthened Glass

Soda lime glass is always chemically strengthened to improve its thermal stability and internal strength. Then glass is thermally tempered by conventional tempering furnace by air quenching to it turn into Class C monolithic fire resistant glass. Xinology FR series fire resistant production system is used to carry out this process to produce Class C fire resistant glass.

Metallic Coated Glass

Glass could be metallic coated on both sides to reflect away heat and minimize the possibility of thermal shock. Monolithic fire resistant glass performs consistent regardless of fire attack direction.

Borosilicate Glass

Borosilicate glass is excellent in heat proof. It has also very low coefficient of thermal expansion to resist thermal shock. Borosilicate glass is generally fully thermal tempered upgraded to fire resistant glass.

Glass Ceramic

It is a special composition of glass and ceramic with excellent thermal shock and heat insulation.

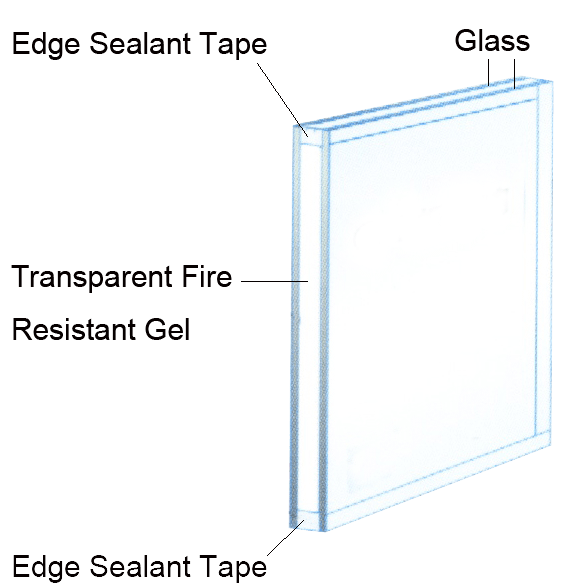

Double Layers Fire Resistant Glass

This laminated double layers fire resistance glass is made with multiple laminate of float glass with special transparent intumescent interlayer, fire resistant gels and resins. There are several popular gels and resins available in the market. Proper materials are chosen mainly depending on required time and fire-resistance class to be achieved in respect to integrity, heat irradiation and heat insulation. They may also have different characteristics including optical property, light transparency, haze, syneresis property, streak look, acoustic insulation, specific gravity, UV resistant and anti-aging, etc.

When fire is broken out, fire side of laminated glass sometimes fractures but interlayer holds them firmly to keep them in place. As temperature gets higher, the gels or foam always become opaque and intumesce with heat insulated and radiation proof to shield flame, smoke, fume and poison gas. The intumescent interlayer prevents radiation heat which could cause combustion on non-fire side. They also provide heat insulation to keep temperature of non-fire side as low as possible. These enable a safe and panic free evacuation at fire scene.

If higher levels of fire proof standard are required, Class C monolithic glass, instead of ordinary annealed soda lime glass, is always upgraded by intumescent glass lamination.

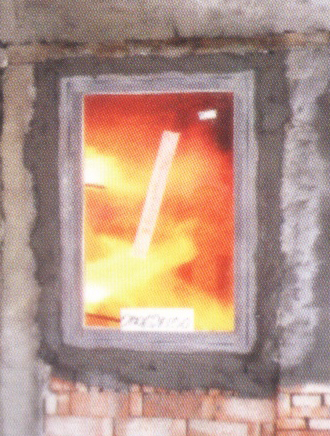

Testing of Double Layer Laminated Fire Resistant Glass