Features & Specs

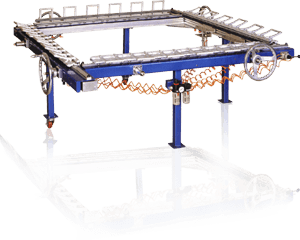

Mechanical Stretching Equipments

- SPE-ST-M screen tensioning device pulls & stretches fabric in all directions mechanically by hand wheels

- Composed of frame structure, thread screw mechanism, chain transmission mechanism, clamping & pneumatic system

- Table structure consists of four identical metal beams connecting to each other at right angle forming a sturdy rectangular frame structure

- Mechanical chain transmission & trapezoid thread screw for precision stretching movement with self-lock system

- Simply turns hand wheel & fabric is stretched

- Dependable non-slipping jigs & fixtures hold fabric firmly in place

- Sophisticated design & structure guarantees consistent tensile strength across fabric

- Fastest & easiest & reliable way for fabric stretching

- Fabric edges come to contact with frames by pneumatic cylinders

- Cylinder stroke length is adjustable by screw meeting different frame thicknesses

- No fabric is damaged with proper regulated stable pneumatic pressure

| Models | SPE-ST-M |

| Max. Fabric Size | 1500 x 2100 mm |

| Min. Fabric Size | 700 x 700 mm |

| Max. Tensile Strength | 50 N/cm2 ± 0.7 N/cm2 |

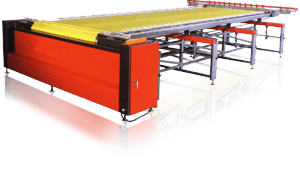

Electrical Stretching Equipments

- Electrically driven SPE-ST-E stretches silk screen fabric in all directions automatically

- Pre-loaded screen roll minimizes fabric loading time

- Process fabric up to 5500 mm in length

- Dependable non-slipping jigs & fixtures hold fabric firmly in place

- Sophisticated design & structure guarantees consistent tensile strength across fabric

- Fastest & easiest & reliable way for fabric stretching at minimum labour force

| Model | SPE-ST-E |

| Max. Fabric Size | 2300 x 5500 mm |

| Min. Fabric Size | 500 x 700 mm |

| Tensile Strength Accuracy | ± 0.5N |

| Power | 2.5 kW |

| Voltage | 380V / 3 Phase / 50 Hz (others on request) |

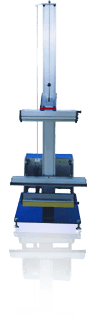

Single Surface Emulsion Coating Machine

- SPE-EC-S applies emulsion on single side of fabric

- Automatic emulsion coating

- Consistent up & down squeegee bars movement

- Uniform coating of emulsion across fabric

| Model | SPE-EC-S |

| Max. Fabric Size | 1250 x 1500 mm |

| Power | 0.2 kW |

| Voltage | 220V / 1 Phase / 50 Hz (others on request) |

Double Surfaces Emulsion Coating Machine

- SPE-EC-D applies emulsion on double sides of fabric

- PLC controls all sequence

- Program could be upgraded whenever necessary

- HMI touch panel operator interface for fast & easy operation

- High precision pneumatic cylinder ensure fine coating adjustment

- Automatic emulsion coating

- Coating speed regulated by frequency converter

- Sturdy steel structure & linear guide guarantee uniform squeegee bar coating across fabric

| Model | SPE-EC-D |

| Max. Fabric Size | 1200 x 1300 mm |

| Coating Speed | 0 ~ 120 mm/s (adjusted by frequency converter) |

| Coating Repeat Accuracy | �� 1 mm |

| Compress Air | 0.4 ~ 0.8 MPa |

| Power | 0.37 kW |

| Voltage | 380V / 3 Phase / 50 Hz (others on request) |

| Outer Dimensions | 1920(L) x 2100(H) x 580(W) mm |

Drying Cabinet

- SPE-DC is a heating oven design with drawers

- Automatic heating

- Thermostat maintains constant temperature

- Hot air fan re-circulate heat convection

- Uniform heating with consistent drying

| Model | SPE-DC |

| Max. Frame Size | 900 x 1200 mm |

| Temperature | Room temperature ~ 50�� |

| Power | 3.6 kW |

| Voltage | 220V / 1 Phase / 50 Hz (others on request) |

| Outer Dimensions | 1200(L) x 1000(W) |

Vacuum UV Exposure System

- Emulsion exposed under UV with SPE-UVE vacuum UV exposure equipment

- 3 KW cool UV lamp

- Vacuum & exposure times set up in micro-computer

- Store up to 60 different parameters

- Light compensation ensures uniform light intensity

- Stable light source wavelength

- Parabolic light reflection shield

- Up to 80% light reflection efficiency

- High vacuum system evacuates air between film and screen fabric

- Oil free vacuum pump

- Fast start

- Energy save design

- Suitable for exposure of high definition images & high density fabrics

| Model | SPE-UVE |

| Max. Frame Size | 950 x 1200 mm |

| Light Source | 3 kW cool UV lamp |

| Light Transmitted Glass Size | 1100 x 1300 mm |

| Light Reflection | 80% |

| Vacuum Pressure | - 0.08 MPa |

| Power | 3.5 kW |

| Voltage | 220V / 1 Phase / 50 Hz (others on request) |

| Weight | 400 kg |

| Outer Dimensions | 1550(L) x 1400(W) x 1320 mm |